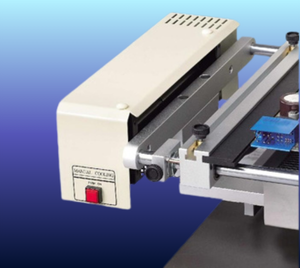

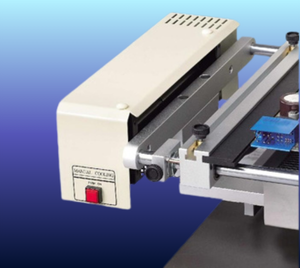

FONTON BGA 936-UA

The FONTON BGA 936-UA is a precision rework system designed for high efficiency and accuracy in BGA rework and repair tasks. It features a unique first different color alignment system, ensuring precise positioning and alignment. Engineered for advanced applications, the system is equipped with customizable hot air flow and a large bottom heating platform.

Overview

The FONTON BGA 936-UA offers a specialized solution for BGA rework with a combination of precision, versatility, and performance. The system includes an ultra-large bottom heating area of 360x260 mm, ensuring uniform heat distribution. Its high-efficiency cooling system and reflow profile inspection system provide reliable, repeatable rework results.

Features

- First Different Color Alignment System for precise alignment.

- Adjustable Hot Air Forcible Guide to optimize airflow control.

- Ultra-Large Bottom Heating Platform (360x260 mm) for uniform heating.

- High Efficiency Cooling System for rapid cooldown.

- Reflow Profile Inspection System to monitor temperature profiles accurately.

Specifications

- Alignment System: First different color alignment technology

- Bottom Heater Size: 360 mm x 260 mm

- Hot Air Guide: Adjustable forcible guide design

- Cooling System: High-efficiency for quick temperature control

- Inspection: Integrated reflow profile inspection system