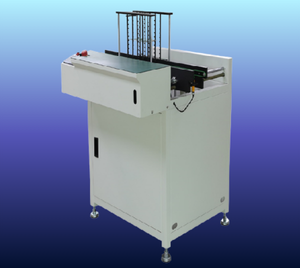

LEAPTECH REJECT CONVEYOR

Efficient NG Board Handling with Seamless Pass-Through The LEAPTECH REJECT CONVEYOR is designed to be installed after AOI inspection for efficient separation of NG (No Good) boards for visual inspection while allowing OK boards to pass through without stopping. Featuring PLC program control, this conveyor enhances production line automation and quality control.

Overview

The conveyor includes start/stop pushbuttons, center PCB stop positioning, and a touchscreen control panel for intuitive operation. It is built with an anti-static conveyor belt that is easy to replace, and it offers both reject and bypass modes for flexible line configurations. The heavy-duty base prevents shifting, ensuring precise PCB stopping.

Features

- Post-AOI Operation: Separates NG boards for inspection while passing good boards seamlessly.

- PLC Program Control: Ensures reliable and automated operation.

- User Interface:

- Start/Stop pushbutton.

- Center PCB stop positioning.

- Touchscreen control panel.

- Anti-Static Conveyor Belt: Easy replacement design.

- Mode Selection: Switch between reject mode and bypass mode.

- Stable Design: Heavy bottom construction prevents movement during operation.

- Precise PCB Stopping: Ensures accurate board positioning.

- Width Adjustment: Smooth and parallel adjustment with lead screw mechanism.

- SMEMA Compatible: Easily integrates with standard SMT lines.

Specifications

- Control: PLC program control with touchscreen interface

- Conveyor Belt: Anti-static, easy replacement

- Modes: Reject and Bypass selectable

- Adjustment: Lead screw-based smooth width adjustment

- Operation: Start/Stop pushbutton, center PCB stop

- Structure: Heavy-duty base for stability

- Compatibility: SMEMA standard