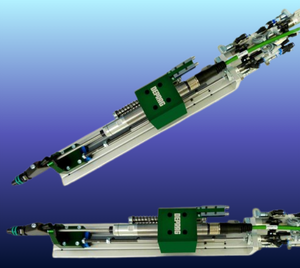

SCREWDRIVER FUNCTION MODULES (SFM)

Screwdriver Function Modules are the foundation of automated and process-reliable screw assembly. The SFM range covers a wide torque spectrum and is available in both single- and multi-spindle configurations. The modular design is structured around six standardized variants, allowing tailored solutions for diverse assembly needs.

Overview

The Screwdriver Function Modules (SFM) are essential components in automated screw-assembly processes, ensuring precision and reliability across a wide range of torque requirements. Designed with flexibility in mind, the SFM units support both single- and multi-spindle operations and can be configured to fit various assembly environments and constraints. The modularity of the system enables seamless integration into production lines, boosting efficiency and assembly quality.

Features

- Wide Torque Range: Suitable for applications requiring both low and high torque specifications.

- Single & Multi-Spindle Options: Configurable based on production volume and complexity.

- Modular Design: Allows easy customization with six different standard designs.

- High Process Reliability: Ensures consistent and accurate screw assembly.

- Flexible Orientation: Compatible with horizontal, vertical, and inverted assembly positions.

- Compact Solutions: Available in space-saving configurations for constrained environments.

Specifications

- Standard Execution: A slender design optimized for horizontal or vertical screwdriving.

- Short Execution: Tailored for applications with restricted space access.

- Underfloor Execution: Designed for vertical, inverted assembly tasks.

- Vacuum Execution: Ideal for hard-to-reach or recessed screw locations in any assembly direction.

- Pick & Place Execution: Facilitates fastener placement at a defined pick position.

- Nut Execution: Enables automatic feeding and assembly of nuts.