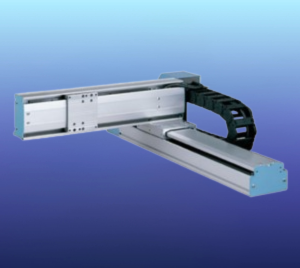

Yamaha Cartesian Robot XY-X Series

The XY-X Series is a modular Cartesian robot from Yamaha, consisting of 2 to 6 orthogonal slide axes. With a broad range of arm sizes and functions, it offers solutions from compact, cost-effective models to heavy-duty, long-distance transfer systems—meeting diverse automation requirements.

Overview

Engineered for flexibility and performance, the XY-X Series is suited for tasks that demand high accuracy, long travel, and multi-axis motion. These robots are widely used in industries requiring precise and repetitive operations such as assembly, machining, insertion, and packaging—especially for small precision components, automotive parts, and PCB-mounted electronics.

Features

- 2–6 orthogonal axes for multi-directional movement

- Modular slide combinations to suit custom layouts

- Supports compact, mid-size, and heavy-load applications

- High-rigidity structure for long-distance and high-speed transfer

- Cost-efficient solutions for complex automation setups

- Excellent repeatability for consistent performance

- Easy integration with gantry or pick & place systems

- Available in multiple stroke lengths and payload capacities

- Suitable for precision handling, machining, and packaging tasks

Specifications

- Axis Count: 2 to 6 axes (orthogonally aligned)

- Drive Type: Belt + ball screw + linear guide (model-dependent)

- Stroke Range: Customizable (commonly up to 1500 mm per axis)

- Repeatability: ±0.01 to ±0.02 mm

- Payload Capacity: Varies by model (light to heavy-duty capable)

- Speed: High-speed transfer support (model-dependent)

- Installation: Horizontal or gantry-style configurations

- Typical Applications: Assembly and part insertion , PCB board component handling, Automotive parts packaging , Small machinery precision machining , Transfer and pick & place operations