LEAPTECH AUTOMATIC LOADER

- This equipment is used for the loading operation of PCBs on the PCB Assembly Line (SMT/ Auto insertion).

- PLC control system.

- LED TFT touch screen control panel.

- Four step pitch selection (10, 20, 30, 40 mm).

- 2 magazines loading capability.

- With the special structure of anti-clamping plate and fool proof.

- Direction from ‘left to right’ or ‘right to left’ (option).

- Standard SMEMA.

LEAPTECH AUTOMATIC UNLOADER

- This equipment is used for the unloading operation of PCBs on the PCB Assembly Line (SMT/ Auto insertion).

- PLC control system.

- LED TFT touch screen control panel.

- Four step pitch selection (10, 20, 30, 40 mm).

- 2 magazines loading capability.

- With the special structure of anti-clamping plate and fool proof.

- Direction from ‘left to right’ or ‘right to left’ (option).

- Standard SMEMA.

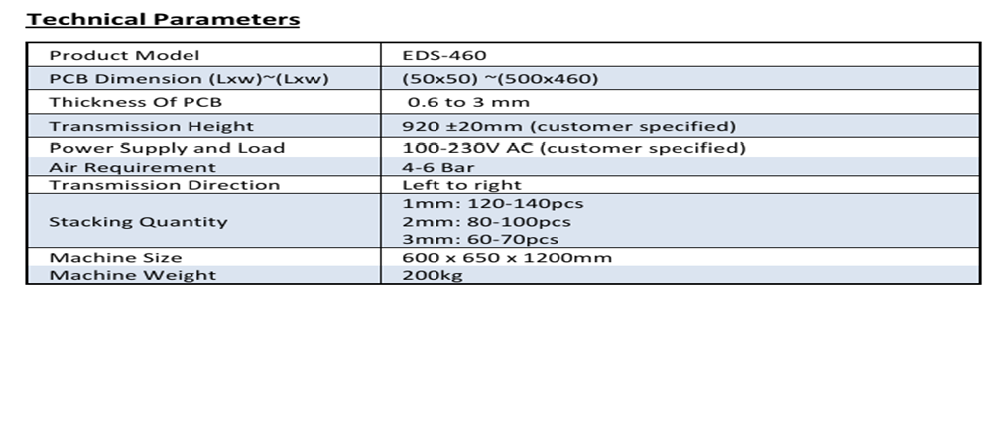

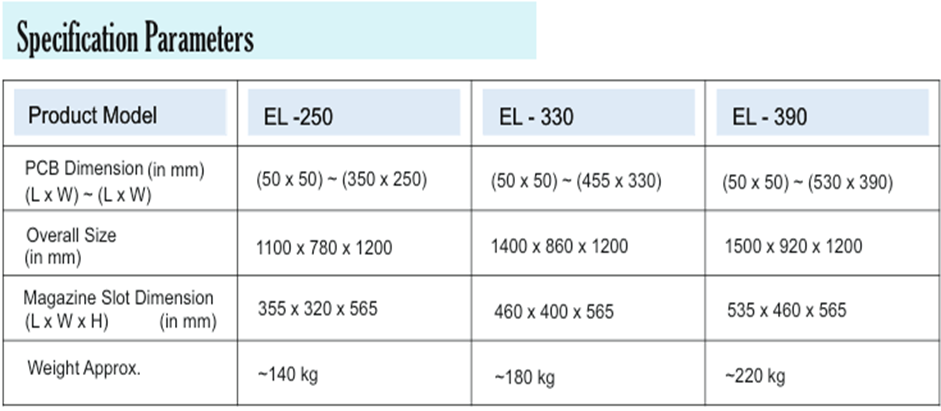

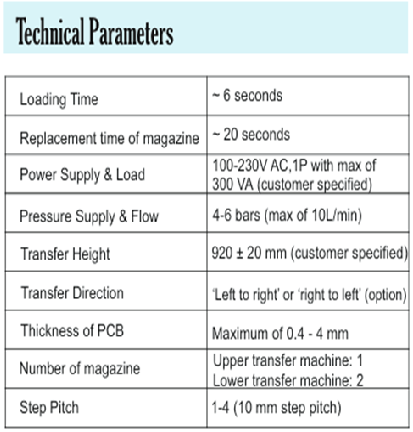

Technical & Specification Parameters - Leaptech Automatic Loader

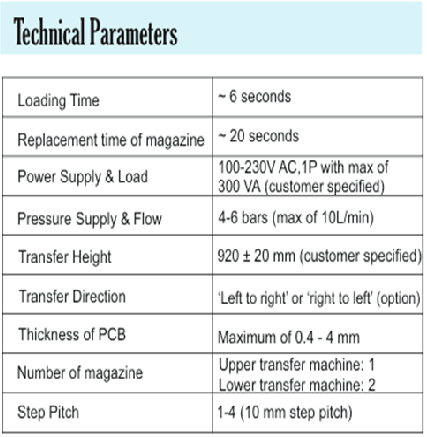

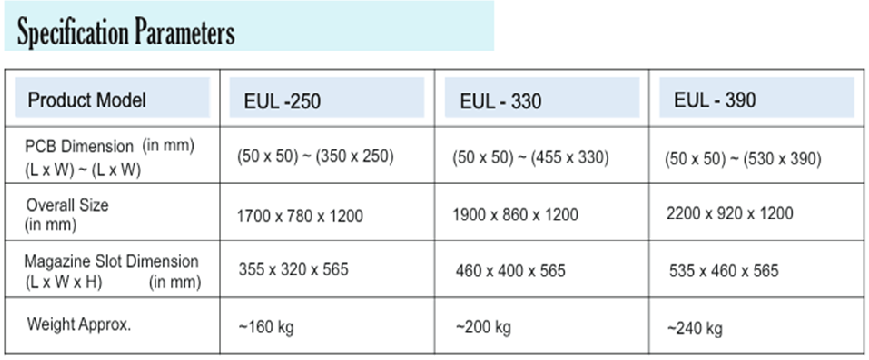

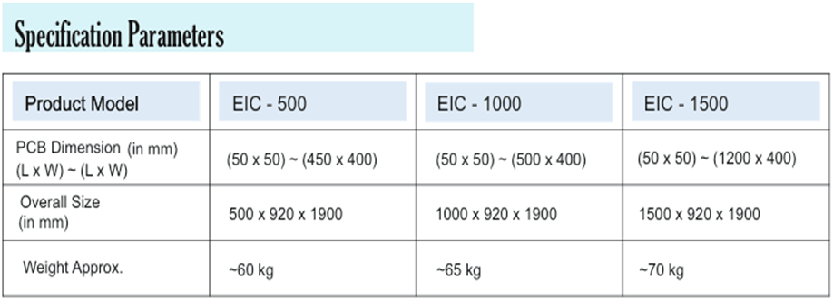

Technical & Specification Parameters - Leaptech Automatic UnLoader

LEAPTECH INSPECTION CONVEYOR

- This equipment is used for visual inspection of the PCBs on the PCB Assembly Line (SMT/ Auto insertion).

- With inspection mode and release button.

- L size, with 3 sensor.

- With Mitsubishi Industrial Control Box.

- Platform material - ESD Rubber/ Aluminium alloy.

- Different lengths available upon request.

- SMEMA Compatible.

LEAPTECH LINK CONVEYOR

- This equipment is used to link between SMD Machines or board handling units.

- L size.

- With Mitsubishi Industrial Control Box.

- Platform material - ESD Rubber/ Aluminium alloy.

- Different lengths available upon request.

- SMEMA Compatible

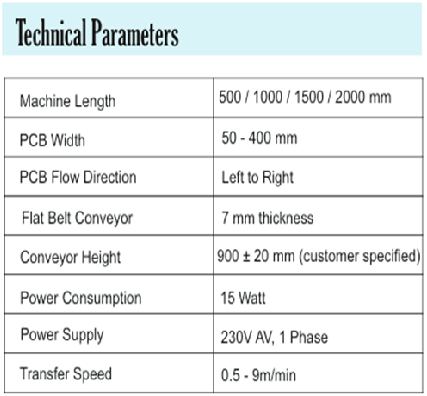

Technical & Specification Parameters - Leaptech Inspection Conveyor

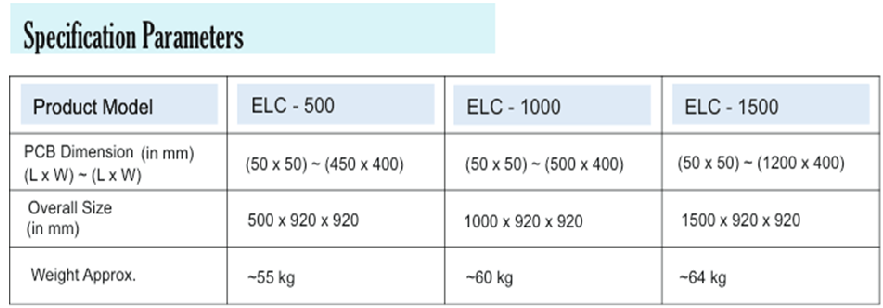

Technical & Specification Parameters - Leaptech Link Conveyor

LEAPTECH POST AOI INSPECTION CONVEYOR

- With Inspection Mode & release button.

- L Size, with 4 Sensor & Sensor for OK/NG identification.

- Can handle PCB size of 1000/1500 / 2000mm length, PCB Width 50 to 460mm & PCB Flow Direction Left to Right.

- 7 mm Flat Belt Conveyor.

- Conveyor Height – 900 (+/- 20mm), 15 Watt speed motor.

- Speed control of 0.5 - 9M/Min, Mitsubishi Industrial Control Board & Flow Left to Right.

- With Electronics Control Box.

- Platform material - ESD Rubber/ Aluminium alloy.

- Power Supply: 230V AV, 1 Phase, Dimensions: 1000/1500/2000mm X 920mm X 1900mm & Weight: 65Kgs/70Kgs / 80Kgs.

- SMEMA Compatible.

LEAPTECH COOLING CONVEYOR

- L Size Conveyor, PCB Width 50 to 460mm & PCB Flow Direction Left to Right.

- 7 mm Flat Belt Conveyor & Conveyor Height – 900 (+/- 20mm).

- 15 Watt speed motor, Speed control of 0.5 ‐ 9M/Min.

- Mitsubishi Industrial Control Board.

- Left to Right flow With Electronics Control Box.

- Platform material - ESD Rubber/ Aluminium alloy.

- Power Supply: 230V AV, 1 Phase, Dimensions: 500/1000/1500/2000mm X 920mm X 920mm.

- Weight: 55/60Kgs/64Kgs / 70Kgs.

LEAPTECH DE-STACKER / VACUUM LOADER

- This equipment is used for the loading operation of board on the SMT production line.

- PLC control system & LED TFT touch screen control panel.

- Automatic storage of OK/NG PCB & Pass through function to send the PCB boards continuously.

- Direction from left to right or right to left(option) & Standard SMEMA.

LEAPTECH PCB OK/NG UNLOADER

- This equipment is used for the unloading operation of PCBs on the SMT production line.

- Strong and Stable mechanical design, PLC control system & LED TFT touch screen control panel.

- With the special structure of anti-clamping plate and foolproof.

- Connections on the back of the AOI to separate the good board and bad board on the production line.

- Direction from left to right or right to left(option).

- Standard SMEMA.

LEAPTECH TURN CONVEYOR

- The turning section is designed with a visible safety shield to ensure the highest level of safety.

- Turning and parallel moving uses a planetary reducer for accurate positioning.

- PLC controller, Rotation degree: 90 ͦ & PCB flow direction left to right or right to left.

- Can handle PCB size L450 x W330 mm & With manual Conveyor Width adjustment.

- Cycle time: 15 Sec.

- 7 mm Flat Belt Conveyor, Conveyor Height: 920 (+/- 20mm) & PCB conveying speed of 0 – 9m/Min.

- Platform Material: ESD Rubber Material / Aluminium Alloy.

- Air Supply: 4 ̴6MPa.

- Power Supply: 230V AV, 1 Phase, 100w.

- Dimension: 800mm X 800mm X 1200mm.

LEAPTECH OUTFEED CONVEYOR

- 1.6Meter Module.

- 400mm width with 2mm imported PVC Belt (ESD).

- Structure (40*60) Aluminium.

- L>R, Adjustable angle,with Cooling Fans.

- Mesh/Belt Conveyor with Speed Control.

- Conveyor width 300MM.

LEAPTECH REJECT CONVEYOR

- The unit installed after AOI for separated NG board for visual inspect and good board will pass through without stopping.

- PLC Program control.

- Start / Stop pushbutton, Centre PCB stop position & Touchscreen control panel.

- Anti-static conveyor belt, Easy way of belt replacement & Reject and by-pass mode selectable.

- Heavy bottom design to prevent shifting, PCB precise stopping in position.

- Smooth and parallel width adjustment.(lead screw).

- SMEMA compatible.

LEAPTECH PCB CLEANER

- This unit can remove glass fiber, dust particles, etc. on top surface of PCB before solder paste printing , and improve production yield. Especially suitable for PCB which is mounted extremely small components.

- PLC Program control & On-line automatic clean.

- All types of dust can be removed.

- Adhesive clean roll removes all dust from rolls.

- Ionizer removes electric static on the PWB.

- Draw-out design for Easy changing of adhesive rolls.

- Preset number of PCB & pre-warning counter to purge adhesive rolls, Automatic conveyor width adjustment.

- SMEMA compatible.

LEAPTECH WAVE INFEED COMVEYOR

- This unit is used for transferring of PCBs/pallets into the soldering machine.

- Robust design.

- Two belt segments.

- Adjustable inclined angle (4o - 7o) or specify.

- Variable speed control to synchronise with wave soldering machine.

- PLC controlled (optional)

- SMEMA compatible.

LEAPTECH DE-STACKER / VACUUM LOADER Technical Parameters